PRODUCTS CENTER

● More than 1000 hours of service life to achieve low cost of ownership ● The infrared unit will not weaken over time, so it can maintain accurate and consistent response ● Detect R22, R134A, R404A, R410A, R507 (AZ-50), R32, HFO1234yf and all CFCs, HCFCs, HFCs, HFOs refrigerants ● 0.10 oz (3 g)/year sensitivity ● The infrared unit will not be overloaded or "poisoned" even if it is exposed to a large amount of refrigerant ● High efficiency air sampling pump provides quick response and quick clearance ("zeroing") ● The on-board diagnostic program can indicate the charging state and send a low battery or infrared unit fault warning

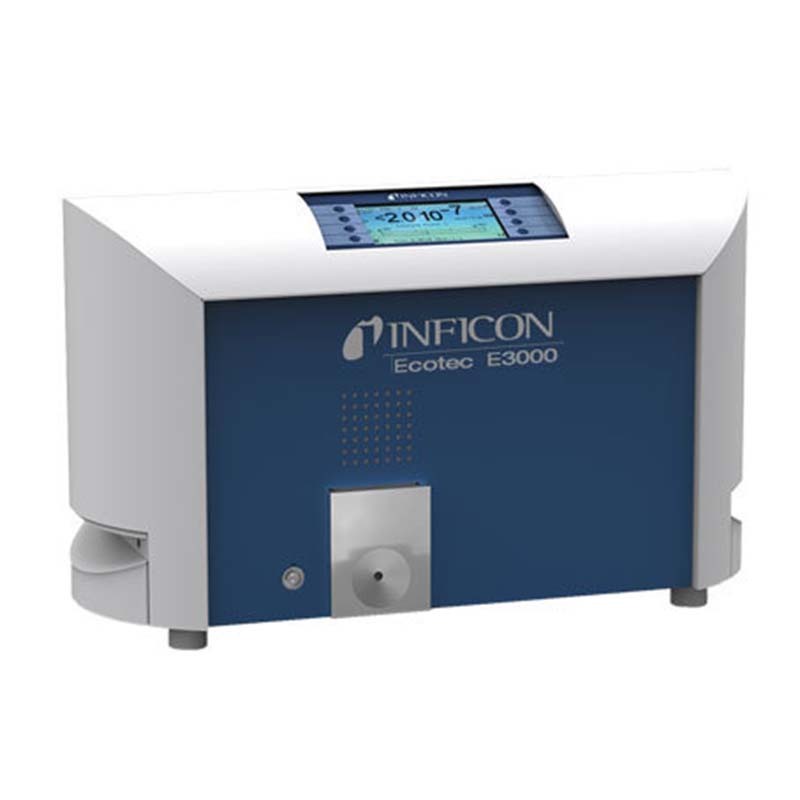

View details● Detect all refrigerants including R600a, R290, CO2, HFO-1234yf and fuel; ● The improved system design compensates for poor suction gun operation and reduces the possibility of omission; ● IGS (interference gas suppression) ensures that only leaks are detected; ● Multiple alarms ensure that leakage will not be ignored; ● I-Guide (operator guidance mode) ensures that the operator is using the correct technology to test the correct position; ● Built in ECO Check reference leak allows simple and rapid calibration in the production line at any time; ● Provide multilingual operation software;

View details● Detect all refrigerants including R600a, R290, CO2, HFO-1234yf and fuel; ● Exquisite and small suction probe, ergonomically designed, equipped with status display and LED light; ● Touch screen shall be used to visually display the chart data of leakage rate; ● USB interface can be used for measuring data storage and software version update; ● The newly designed COOL Check bracket is easy to replace the built-in leak; ● Equipped with separate CO2 suction probe, R600a/R290 and general intelligent halogen based refrigerant suction probe; ● The HLD6000 adopts an infrared sensor, which is characterized by long service life, high sensitivity and fast response, and is specially used for refrigerant detection; ● The optional I/O module and the optional field bus module are used to facilitate the integration with the local network.

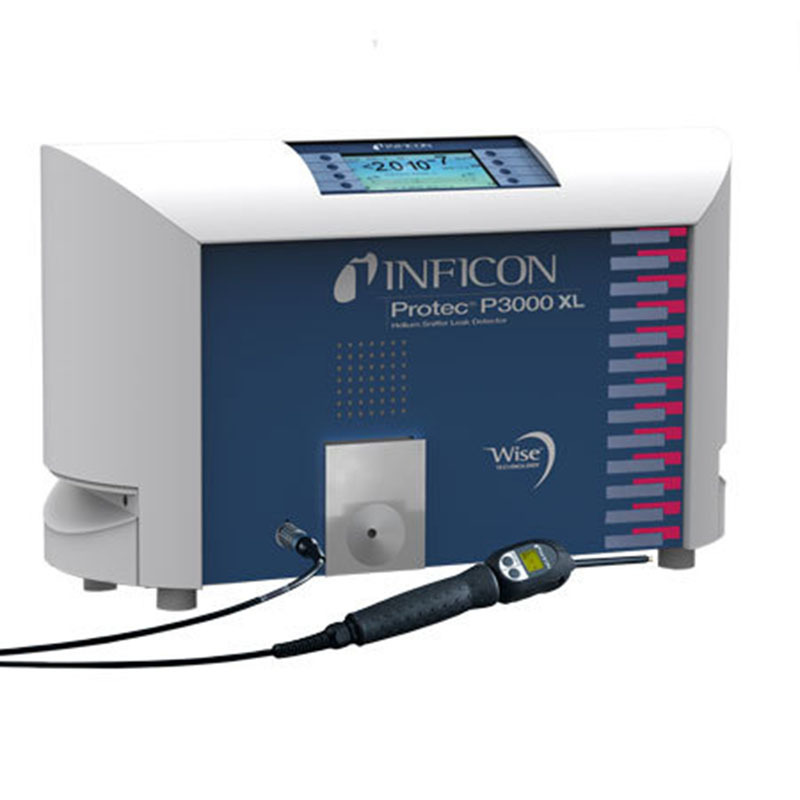

View details● I-Guide operator guidance mode ensures that the operator is using the correct technology to test the correct position; ● Improved system design compensates operator errors and reduces the possibility of omission; ● Multiple alarm functions ensure that the alarm will not be ignored; ● The built-in PRO Check reference leak allows simple and fast calibration in the production line at any time; ● The small display in the handlebar of the ergonomic design probe can display the leakage rate, so the operator can pay close attention to the leakage detection process of the suction gun and monitor the leakage rate at the same time; ● The leakage rate can be displayed using the refrigeration equivalent of the gas reservoir; ● The built-in lighting device of the probe can help accurately locate the tip of the suction gun; ● New and low maintenance sensors have high reliability and low cost of ownership; ● Automatic standby can prevent pollutants from entering the suction gun probe, thus extending the service life of filters and sensors; ● Provide multilingual operation software.

View details